Container for the scroll indicator

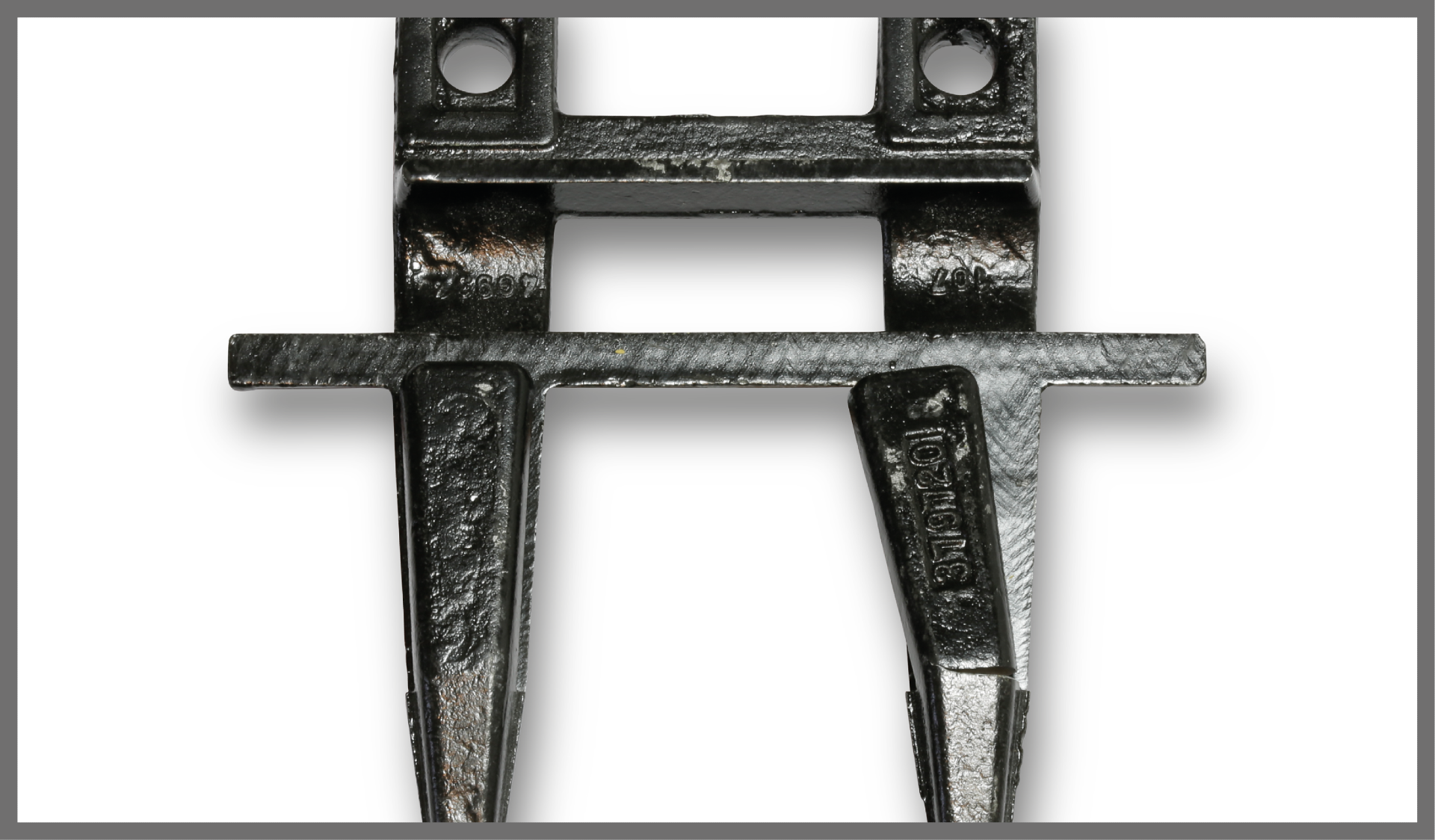

(Will be hidden in the published article)KNIFE GUARD.

MAIN ROLES:

- It’s a guide for the knife bar.

- It plays as counterknife for the knife section to get the best cutting performance in every crop and every harvesting condition.

- It’s a knife protection against material other than crop especially rocks.

EXPECTED CHARACTERISTICS:

- Perfect shape to guide the knife bar with reduced friction and wear.

- Keep its original shape against load and shocks. It must not bend or break easily.

- Bending can generate damages or additional wear on the knife. Beside it will impact the cutting efficiency.

- Breakage will impact directly the cutting performance.

TO EVALUATE AND GUARANTEE THE QUALITY OF ITS GUARDS, NEW HOLLAND HAS DEVELOPED SPECIFIC TEST PROCEDURE TO MATCH THE BEHAVIOR IN THE FIELDS

- Bend test on the leg.

- Bend test on the lip.

- Tensile on the lip.

The test procedure defines the minimum load for which no bending and no crack is accepted on the part

Competitor sample failed at bending test

Competitor sample failed at bending test

COMPETITOR PARTS INTEND TO COPY THE NEW HOLLAND GUARD. BUT NONE OF THEM CAN PASS SUCCESSFULLY EVERY TEST PROCEDURE.

Competitor sample failed at bending test

Competitor sample failed at bending test

OUT OF SIX DIFFERENT COMPETITOR PARTS SAMPLES, NONE OF THEM CAN SUPPORT THE LOAD AND THE SHOCKS THAT A NEW HOLLAND GENUINE FINGER IS ABLE TO ABSORB.

Competitor samples bend instead of breaking.

Competitor samples bend orbreak but not always atthe groove where they should break

Other samples break but with too much lower energy.

OUT OF SIX DIFFERENT COMPETITOR PARTS SAMPLES, NONE OF THEM CAN SUPPORT THE LOAD AND THE SHOCKS THAT A NEW HOLLAND GENUINE FINGER IS ABLE TO ABSORB.

Do you know?

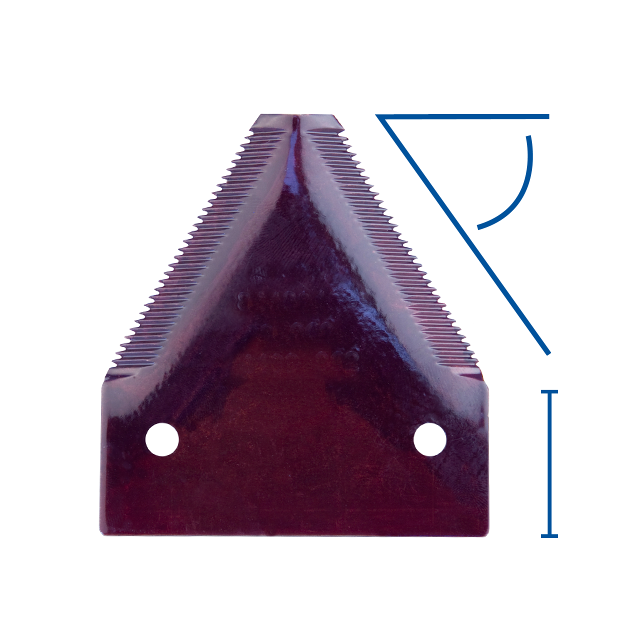

For the best cutting performance in every condition, you can select from New Holland product offer different knife section models

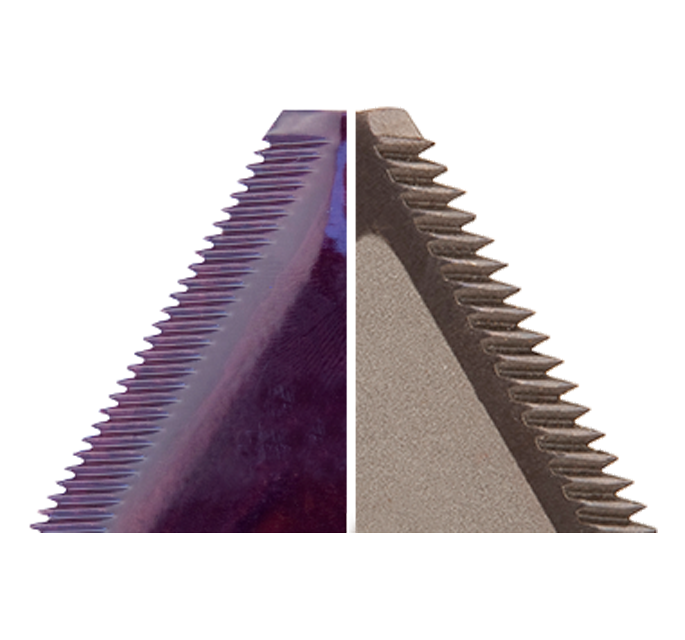

COARSE SECTION

COARSE SECTION

KEY BENEFITS

- With bigger serrations, they can support harvesting in harsh conditions, difficult to cut.

- They are also efficient in very dry straw conditions

DON’T FORGET

Being more aggressive, they can create more vibrations to the crops so should not be used on crops sensitive to grain loss.

| | Knife section | ||

|---|---|---|---|

| Grain Header | Standard | Green conditions | Coarse serration |

| Varifeed 760CG | 47980548 | 47983317 | 87728905 |

| High capacity | 84429103 | 84435879 | 47372755 |

At any time find parts online through MyCNHIStore.com.

On the Mycnhistore e-commerce site, you have access to all the spare parts available New Holland brand, from the filters in your cab to the bearings, from the engine oil to all the accessories for your agricultural machine.

GREEN CONDITION SECTION

GREEN CONDITION SECTION